HAKKO CORPORATION

- Tip temperature thermometer with the traceability management system

- Free of errors in temperature measurement

- Free of transcription errors for measured temperature

- Standardization of temperature measurement

- Secure management of tip temperature records

- Long-life sensor AS5000 (with certificate of conformance) is equipped as standard.

Features

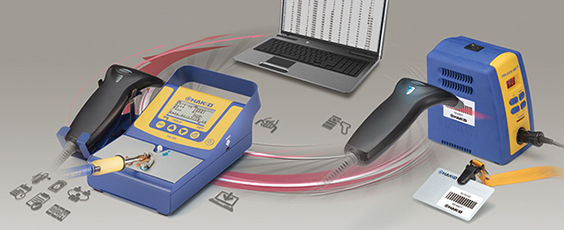

Support to achieve labor-saving in tip temperature control by elimination of a manual process of posting measured temperature and inputting records into computer.

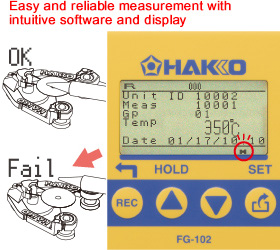

The unit has a function to notify the end of measurement. When measurement is finished, “H” icon stops blinking. The unit can find measurement errors and prompt an operator to repeat measurement. The display shows “Fail” if tip loses appropriate contact with sensor before completion of measurement.

Pass/Fail judgment on measured temperature can be automatically made if an acceptable temperature range is registered in advance. (The display shows “OK” or “Fail”.)

The unit can save up to 300 measurement records and transfer the data to computer via USB. (Data in CSV format. USB cable included.)

Groups can be created based on different set temperatures for different operations. Pass/Fail judgment on measured temperatures can be automatically made for different acceptable temperature ranges.

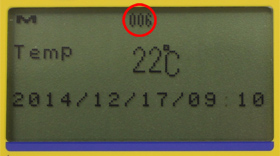

The unit automatically counts the number of measurements which indicates the timing of sensor replacement.

The picture is showing the display after measuring 6 times.

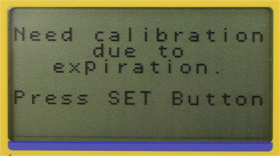

The unit automatically notifies the next scheduled calibration date if it is registered.

When the power is tuned on, this screen is displayed from two weeks before the calibration date.

The unit will automatically enter power save mode if not in operation for a certain time. Power supply to the scanner can be shut off when it is stored in the holder and battery consumption can be reduced.

Excellent portability with a handle and no need for power supply cord.

Compact design makes it easy to carry a unit around in workplace.

| Model No. | FG102-82 |

|---|---|

| Power supply | AA sized (LR6) battery × 6 (alkaline cell recommended) |

| Temperature resolution | 1ºC |

| Temperature measurement range | 0 to 700ºC |

| Temperature precision | ±3ºC (300 to 600ºC) ±5ºC (other than above) |

| Temperature sensor | K (CA)type thermocouple |

| Display | LCD |

| Operating environment | Ambient temperature/humidity range : 0 to 40ºC, 20 to 90%RH (without condensation) |

| Environmental conditions | Applicable rated pollution degree 2 (according to IEC/UL 61010-1) |

| Dimensions | 193(W)× 90(H)× 219(D)mm |

| Weight | 0.93kg |

* Dimensions : excluding barcode reader

* Weight (excluing battery and barcode reader)

* Temperature sensor (No.191-212 or No.191-212C) can only be used ti measure temperatures below 500ºC. To measure higher temperatures, use an applicable temperature probe.

* Traceability management function can only be used for soldering irons.

- Unit,

- Battery (qty 6, for trial),

- Barcode reader,

- USB cable,

- Software (CD-ROM),

- Sensor (qty 10),

- Barcode sticker for soldering iron ID (qty 30),

- Barcode sticker for operator ID (qty 30),

- Instruction manual

| Replacement | Part No. | Name | Specifications |

|---|---|---|---|

| C5009 | Bar code reader | |

| AS5000 | Sensor | lead-free w/cert conformance |

Change-out rate of sensor

The sensor replacement period is about 50 times per single sensor in general, but this changes depending on the temperature used and the components in the solder and flux.

If you use lead-free solder, the sensor needs to be replaced more frequently.

If the sensor degrades because it is being eaten away by the solder, it will register a low temperature. Even if the sensor is not broken, replace it after about 50 measurements.

| Option | Part No. | Name | Specifications |

|---|---|---|---|

| A1310 | Temperature probe | for soldering bath & pot |

| C1541 | Temperature probe | hot air |

| A1556 | Sensor A | |

| A1557 | Sensor B |