HAKKO CORPORATION

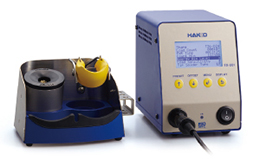

Hakko FN-1010: Enables human error-free temperature control and traceability of manual soldering process

- Improve traceability

- Minimize human error

- Optimize soldering conditions

Features

Pioneer the future of soldering with advanced IoT technology

Optimization of soldering conditions is now possible based on a variety of information in daily soldering process collected by FN-1010.

・Information to be collected

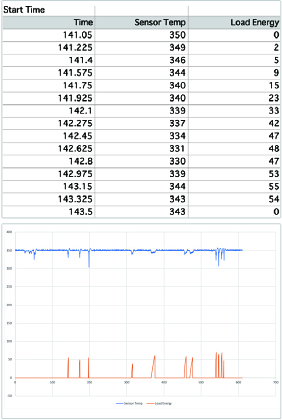

The following information can be collected by memory chip in T36 series tip and saved in a computer through a soldering station.

●Tip shape ●Tip Serial number ●Number of loads ●Total time of power supplied ●Load sensitivity ●Type of solder alloy (Lead-Free / Lead) ●Count alarm

Human error-free “tip temperature calibration ” and “off-set” can be established through daily manual soldering process.

Results of measurement/calibration/off-set can be recorded automatically.

It is now possible to visualize invisible energy supplied from T36 series tip during soldering. And that makes it possible to control factors of soldering, which were impossible before.

Quick access to “Preset temperatures” and “Off-set mode” with one push.

It takes few button operation to access to most frequently used functions.

- The alarm can be notified with vibration in a noisy environment.

- Built-in motion sensor detects free fall and cuts the power.

It can prevent burning floor, fire and other accident with the heat.

Solder ball during tip cleaning can be reduced by 99% with devised cleaner designs such as smaller aperture, and set angle as well as position.

- In-house comparison

| Model No. | FN-1010 |

|---|---|

| Power consumption | 100W |

| Temperature range | 50 to 450ºC |

| Temperature stability | ±3ºC |

| Station | |

|---|---|

| Output voltage | AC 21V |

| Dimensions | 104(W)×138(H)×152(D)mm |

| Weight | 1.9kg |

| Soldering Iron | |

|---|---|

| Power consumption | 95W (21V) |

| Tip to ground resistance | <2Ω |

| Tip to ground potential | <2mV |

| Heating element | Composite heater |

| Cord length | 1.2m |

| Total length | 180mm (with 2.4D tip) |

| Weight | 32g (with 2.4D tip) |

* Total length and weight (w/o cord)

- Station,

- Handpiece (FN-1101)

- Tip cleaner (FT-401, with cleaning wire)

- Power code

- Iron holder (FH-210)

- Instruction manual

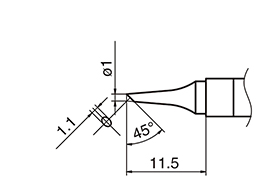

>> Click here to see the T36 Series Tips.