HAKKO CORPORATION

Hakko FR-811 Introducing a high-spec hot air rework station with excellent cost performance. Operate on a computer with the dedicated software

- Possible to make full-scale thermal profiles with 6-zone hot air and a bottom heater.

- Possible to measure and record the temperature of components and PWB with type K thermocouple.

- The dedicated software to link a station and a computer for easy and quick settings.

- Easy data transfer through a USB cable.

Features

A low-cost SMD rework can be assembled with FR-811, dedicated software, and options.

・Possible to make full-scale thermal profiles with 6-zone hot air and a bottom heater.

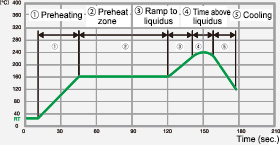

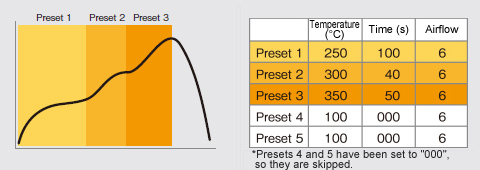

A basic thermal profile is composed of the 5 parts shown above. FR-811 can provide 6 zones in which temperature, time, and air flow are controlled. Therefore FR-811 can make a full-scale thermal profile which is close to reflow profiles made by a reflow oven.

・Record thermal data

By connecting a thermocouple included with FR-811, the temperature of the component or circuit board can be measured and recorded. In addition, if “TC LINK” is set, the heater output can be automatically controlled so that the temperature of the thermocouple attached to the component or circuit board follows the set profile.

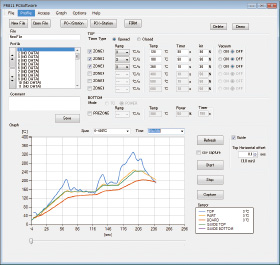

・Operation on a PC for various settings

By connecting FR-811 and a computer with a USB cable and using the dedicated software which comes as standard, a set thermal profile and actual temperature change can be shown in a graph in real time. Also, change of thermal profile and fine adjustment in a profile can be made on computer operation. (After making changes, it is necessary to resend the data to FR-811.)

In addition, the set values and graph can be saved in CSV format. *Click the image to enlarge

・Linked operation with bottom heater

FR-811 can control on/off timing and output of the bottom heater, which is available optionally.

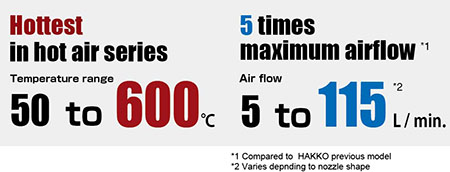

A tool that can provide powerful hot airflow for repairing high heat capacity circuit boards that require high blow volume and high output, and sufficient hot airflow for appropriate blow volume and high output for high-density mounting substrates.

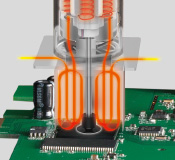

・New type of nozzles for improving temperature characteristics

The new nozzles improve work efficiency with uniform heating by hot air convection inside the nozzle which is created due to vents on the nozzle top. (Only with BGA nozzles)

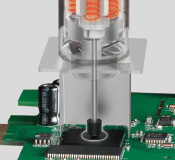

・Vacuum pickup function

The vacuum pickup function is to pick up a component with a suction pad and vacuum.

It will pick a component only after the hot air melts solder joints. This can avoid an error to peel off the land by removing a component with excessive force.

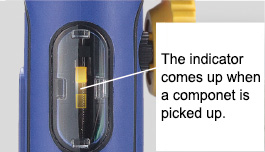

・Pickup indicator

By pre-setting pickup function, a component can be picked up automatically when the solder is melted. At the same time, the indication comes up and the moment of picking up will be visible. Even a component and solder joints cannot be seen as covered by a nozzle, easy and safe picking up is possible.

・Easy-to-read LCD

Equipped with a high-visibility LCD to make it easy to check the various product settings or operation status. Indications are displayed using graphics as well as letters and numbers so information can be checked intuitively.

・Easy-to-operate multi-direction control knob

The multi-direction control knob makes it easy to make and change settings shown in the LCD.

There are several ways of knob movements, dialing, pressing, and tilting up and down and left to right for quick operation.

・Link to a PC (A USB I/F terminal available)

A USB I/F terminal is available to link to a computer. The dedicated software, which can display and record various settings or temperature data on a computer screen in real time, is included.

・A USB device terminal for easy data transfer

Data can be transferred through a USB memory even without a computer.

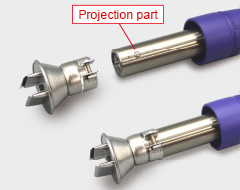

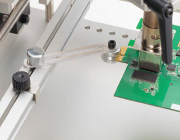

Align the projection part, attach the conventional nozzle to the heater pipe.

The nozzle can be changed quickly when working with a wide range of components. Conventional HAKKO nozzles can be used by using a special conversion adapter (option).

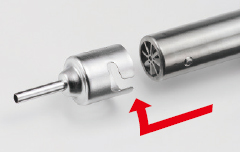

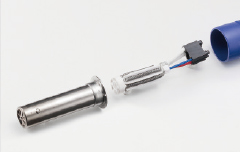

Heater replacement is also simple.

Quick-change N51 nozzles

Simple heater replacement

・Timer function

The timer function is to control the time of operation.

This can help to prevent parts from overheating and can improve the overall quality of rework.

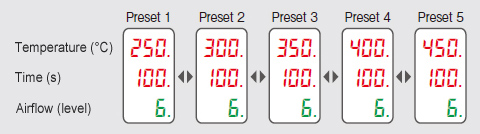

・Chain presets function for making a simple thermal profile

The chain presets function is to make a simple thermal profile by combining several preset conditions. (Up to 5 steps)

This can improve work efficiency a lot by standardizing work time, avoiding overheating, improving repeatability of operation, and making difficult rework jobs easy.

To ensure safety and conserve power, when the handpiece is placed in the handpiece holder, the auto sleep function will be activated and it will start cooling automatically.

If the handpiece has not been removed from the handpiece holder (e.g. Using it in a rework fixture) and it has been idle for 30 minutes, auto shutoff function will be activated. It will be automatically powered off. Access to settings can be restricted by the password function.

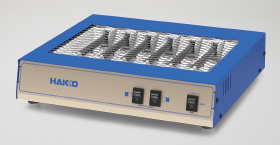

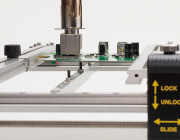

A low-cost rework system can be assembled with a bottom heater, a grip fixture, and a board holder.

Grip Fixture L

Grip Fixture M

A dedicated bottom heater for FR-811

Heating area is divided into 2 sections.

Board Holder

Board Clip

Board Support Unit

| Model No. | FR811-07 |

|---|---|

| Power consumption | AC220V:1,100W |

| Temperature range | 50 to 600ºC |

| Station | |

|---|---|

| Power consumption | 30W |

| Air flow | 001-100% (5 to 115L/min.) |

| Dimensions | 160(W)×145(H)×220(D)mm |

| Weight | 1.5kg |

| Handpiece (Hot air) | |

|---|---|

| Power consumption | AC220V:1,070W |

| Total length | 250mm |

| Weight | 180g |

* Total length and weight for handpiece (w/o cord)

* Airflow capacity is rated as free-flowing. Restrictions created by various nozzles may reduce the maximum airflow capacity.

- Station with handpiece,

- Grip stand assembly

- Vacuum pipe control knob (with screw)

- Pads (Qty 2 each of Ø3 mm, Ø5 mm, Ø7.6 mm)

- USB cable

- Software (CD-ROM)

- Thermocouple

- Heat resistant pad

- Power Cord

- Temperature distribution chart

- Instruction manual

| N51-50 Nozzle Set | |

|---|---|

| N51-01 | 2.5 mm Vacuum function inoperative nozzle |

| N51-03 | 5.5 mm |

| N51-04 | 7 mm |

| N51-05 | 1.5x3 mm/45° |

| Single | |

|---|---|

| N51-01 | 2.5 mm Vacuum function inoperative nozzle |

| N51-02 | 4 mm |

| N51-03 | 5.5 mm |

| N51-04 | 7 mm |

| Bent Single | |

|---|---|

| N51-05 | 1.5x3 mm/45° Vacuum function inoperative nozzle |

| BGA | |

|---|---|

| N51-10 | Size 4×4 mm |

| N51-11 | Size 6×6 mm |

| N51-12 | Size 8×8 mm |

| N51-13 | Size 10×10 mm |

| N51-14 | Size 12×12 mm |

| N51-15 | Size 14×14 mm |

| N51-16 | Size 15×15 mm |

| N51-17 | Size 17×17 mm |

| N51-18 | Size 18×18 mm |

| N51-19 | Size 20×20 mm |

| N51-20 | Size 22×22 mm |

| N51-21 | Size 24×24 mm |

| N51-22 | Size 27×27 mm |

| N51-23 | Size 29×29 mm |

| N51-24 | Size 35×35 mm |

| N51-25 | Size 38×38 mm |

| N51-26 | Size 40×40 mm |

>>Click here for Replacement Parts and Option.